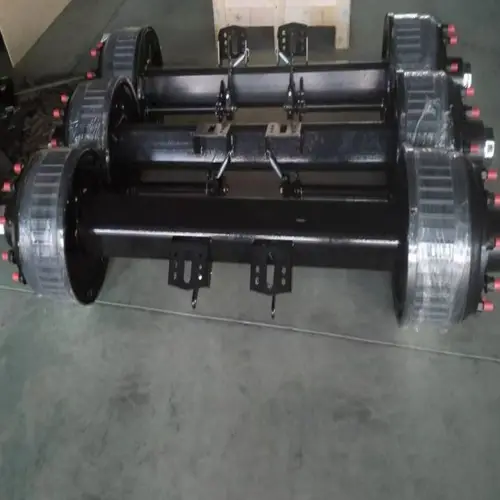

Hydraulic Brake BPW Trailer Axle for Sale

Our Hydraulic Brake BPW Trailer Axle is a high-quality and reliable trailer part that is perfect for your truck axle needs. With great quality and durability, this trailer axle is designed to provide superior performance and long-lasting use.

Product Description

The Hydraulic Brake BPW Trailer Axle is a versatile and efficient axle that is suitable for various types of trailers. It features a maximum capacity of 8 tons, a track width of 1850mm, and a brake size of 420*150mm. The axle beam measures 127mm and the centre distance of the brake chamber is 428mm. With a recommended wheel size of 7.5V-20, this trailer axle is designed to meet your specific needs.

Key Features:

- Max Capacity: 8 tons

- Track Width: 1850mm

- Brake Size: 420*150mm

- Axle Beam: 127mm

- Centre Distance of Brake Chamber: 428mm

- Wheel Fixing: 10*M22*1.5 ISO

- Total Length: ~2145mm

- Recommended Wheel: 7.5V-20

- Axle Weight: 323kg

With its robust construction and excellent performance, the Hydraulic Brake BPW Trailer Axle is a reliable choice for your trailer axle needs. It is designed to withstand heavy loads and provide smooth and efficient operation. Trust this trailer axle to deliver exceptional performance and durability for your truck or trailer.

Frequently Asked Questions

1. What is the maximum capacity of the Hydraulic Brake BPW Trailer Axle?

The maximum capacity of the Hydraulic Brake BPW Trailer Axle is 8 tons, making it suitable for various types of trailers.

2. What is the recommended wheel size for this trailer axle?

The recommended wheel size for the Hydraulic Brake BPW Trailer Axle is 7.5V-20, ensuring optimal performance and stability.

3. What is the track width of this trailer axle?

The track width of the Hydraulic Brake BPW Trailer Axle is 1850mm, providing stability and control during transportation.

4. Is the Hydraulic Brake BPW Trailer Axle suitable for heavy-duty applications?

Yes, the Hydraulic Brake BPW Trailer Axle is designed to withstand heavy loads and is suitable for heavy-duty applications.

5. Can I customize the Hydraulic Brake BPW Trailer Axle according to my specific requirements?

Yes, we welcome customization requests. Please provide us with drawings or samples, and our team will work with you to meet your specific needs.

At our company, we not only specialize in Hydraulic Brake BPW Trailer Axles but also offer a wide range of industrial products. From agricultural gearboxes to power output shafts, sprockets to hydraulic couplings, we have the solutions for your diverse needs. Our products are known for their high quality, competitive prices, and exceptional service. Customer satisfaction is our top priority, and we are committed to providing you with the best products and services.

Performance Characteristics of Trailer Axle

Trailer axles are an essential component of trailers and other vehicles, which enables them to transport goods efficiently and safely. Here are some of the performance characteristics of trailer axles:

1. Load Capacity:

The load capacity of a trailer axle is a crucial factor to consider while purchasing one. It determines the maximum weight that the trailer can carry. The load capacity depends on the size, number of axles, and the material used to manufacture the axle.

2. Durability:

Trailer axles must be durable to handle the load capacity and frequent use. The durability depends on the quality of materials used, manufacturing process, and the design of the axle.

3. Stability and Safety:

Trailer axles must provide stability and safety while transporting goods. The design of the axle, suspension system, and braking system must work together to ensure safe and stable transportation.

4. Compatibility:

Trailer axles must be compatible with the trailer’s size, weight, and other specifications to function correctly.

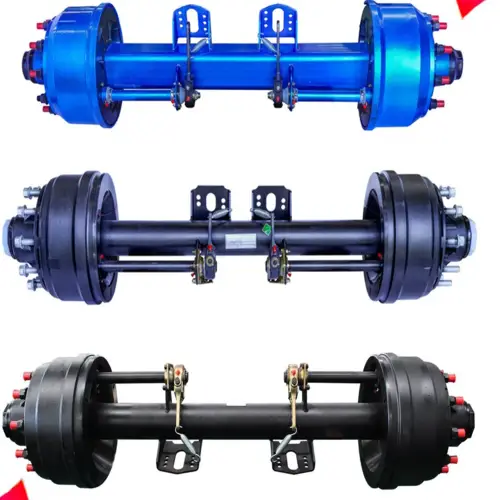

Types and Characteristics of Trailer Axle

Trailer axles come in different types, each with unique characteristics suitable for specific applications. Here are some of the common types:

1. Straight Axle:

Straight axles are the most common type of trailer axle and are suitable for light and medium-duty applications.

2. Drop Axle:

Drop axles are suitable for trailers that need a lower deck height, such as car hauling trailers.

3. Torsion Axle:

Torsion axles provide a smoother ride and better suspension than straight or drop axles. They are suitable for heavy-duty applications.

Trailer axles come in different materials, including steel, aluminum, and iron. The choice of material depends on the application and the load capacity required. Steel axles are durable and can handle heavy loads, while aluminum axles are lightweight and suitable for light-duty applications.

Applications of Trailer Axle

Trailer axles are essential components in various fields, including Transportation and Logistics, Agriculture, Construction, Specialty Trailers, and Heavy Equipment Transport. Trailer axles are suitable for these fields due to their load capacity, durability, stability, and safety.

Future Development Trends and Opportunities

The trailer axle market is continually evolving, driven by technological advancements and changing customer needs. The future of trailer axles lies in lightweight and durable materials, improved suspension systems, and environmentally friendly designs.

The rise of e-commerce and home delivery services presents an opportunity for trailer axle manufacturers to develop new products to meet the growing demand for transportation and logistics.

How to Choose a Suitable Trailer Axle

Choosing the right trailer axle is crucial for efficient and safe transportation. Here are some factors to consider when choosing a suitable trailer axle:

1. Determine the Load Capacity:

The load capacity of the trailer axle must match the weight of the trailer and the goods to be transported.

2. Choose the Correct Axle Type:

The type of trailer axle must match the trailer’s size, weight, and the number of axles required.

3. Consider the Axle Length and Width:

The length and width of the trailer axle must match the trailer’s dimensions.

4. Choose the Right Material:

The choice of material depends on the application and the load capacity required.

5. Examine the Suspension System:

The suspension system must provide stability and safety while transporting goods.

6. Match the Axle with the Trailer’s Brake Requirements:

The trailer axle must be compatible with the trailer’s braking system to ensure safe transportation.

Conclusion

Trailer axles are essential components in various fields, enabling efficient and safe transportation of goods. When choosing a trailer axle, it is crucial to consider factors such as load capacity, durability, and compatibility with the trailer’s size and weight. The future of trailer axles lies in technological advancements and environmentally friendly designs.

Author: Dream

All the content of the page is from the Internet, the content is only as a reference for product selection, our products are replacement parts and not original spare parts; we are not the holder of the original trademarks of the content, our products are only suitable for after-sales replacement parts and not original spare parts, our replacement parts can be perfectly adapted to the original spare parts; if you need to buy original spare parts, please contact the original factory to buy. If you want to buy original spare parts, please contact the original supplier for purchase.