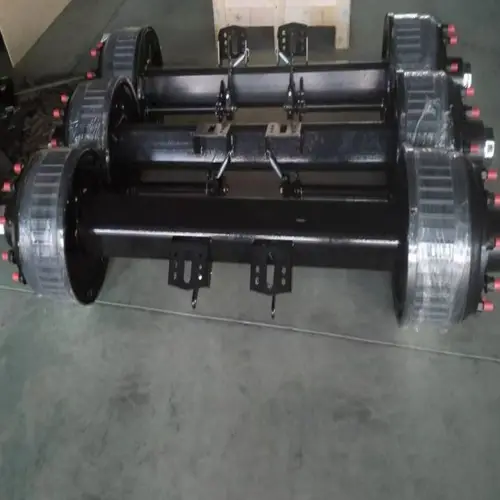

China Standard 12t 14t 16t Semi-Trailer Axle Germany Type Axle with High Quality

Product Description

The China Standard 12t 14t 16t Semi-Trailer Axle Germany Type Axle is a high-quality axle designed for semi-trailers. It is manufactured using special heat-treated, low-alloy steel axle beams, which provide excellent load-bearing capacity while minimizing weight. The axle also features a high-performance premium non-asbestos brake lining for extended service life. With its easy ABS installation and superior sealing properties, this axle ensures safety and reliability. The axle is available in various sizes and capacities, ranging from 12t to 16t. It is compatible with different wheel rims, including ISO, BSF, and JAP, making it suitable for a wide range of applications.

Product Features

- Special heat-treated, low-alloy steel axle beam for excellent load-bearing capacity

- High-quality alloy CHINAMFG inserted spindle for superior fatigue capability

- High-performance premium non-asbestos brake linings for extended service life

- Easy ABS installation

- Camshaft with special seals to prevent grease entry into the brake drum

- New tight-fit hub cap with O rings for superior sealing

- Grease lubricant supplied by Mobil for extended maintenance intervals

- Full range of stud fixing options, including ISO, BSF, and JAP

Scope of Our Business

Our company specializes in manufacturing and supplying a wide range of industrial products. In addition to the China Standard 12t 14t 16t Semi-Trailer Axle Germany Type Axle, we also offer other products such as axles (German type, English type, American type, Spoke type, ZM type, Agriculture type, Half axle, Axle without brake), suspensions (Bogie suspension, One point suspension, Rigid suspension, Spoke suspension, Machinery suspension), landing gears, fifth wheels, king pins, semi-trailers, and other axles and related parts (Low bed axle, hub, rims, spring, drum, etc.). Our products are known for their high quality, competitive prices, and excellent customer service. We welcome customers to customize products based on their drawings and samples.

FAQ

Q1: Are you a factory?

A: Yes, we are a factory with sales team and offices to provide comprehensive support to our buyers and partners.

Q2: What’s your Delivery Time?

A: In general, the delivery time is 15-20 days. We strive to deliver products quickly without compromising quality.

Q3: What is the convenient way to pay?

A: We accept various payment methods, including L/C, T/T, Unionpay, and DP. If you have a better payment option, please let us know.

Q4: Which type of shipping would be better?

A: We recommend sea transportation for its cost-effectiveness and safety. However, we respect your preferences and can arrange alternative transportation methods if needed.

Q5: Can you provide customization services for your products?

A: Yes, we offer customization services based on customers’ drawings and samples. We strive to meet unique requirements and provide tailored solutions.

Performance Characteristics of Trailer Axle

Trailer axles are an essential component of trailers and other vehicles, which enables them to transport goods efficiently and safely. Here are some of the performance characteristics of trailer axles:

1. Load Capacity:

The load capacity of a trailer axle is a crucial factor to consider while purchasing one. It determines the maximum weight that the trailer can carry. The load capacity depends on the size, number of axles, and the material used to manufacture the axle.

2. Durability:

Trailer axles must be durable to handle the load capacity and frequent use. The durability depends on the quality of materials used, manufacturing process, and the design of the axle.

3. Stability and Safety:

Trailer axles must provide stability and safety while transporting goods. The design of the axle, suspension system, and braking system must work together to ensure safe and stable transportation.

4. Compatibility:

Trailer axles must be compatible with the trailer’s size, weight, and other specifications to function correctly.

Types and Characteristics of Trailer Axle

Trailer axles come in different types, each with unique characteristics suitable for specific applications. Here are some of the common types:

1. Straight Axle:

Straight axles are the most common type of trailer axle and are suitable for light and medium-duty applications.

2. Drop Axle:

Drop axles are suitable for trailers that need a lower deck height, such as car hauling trailers.

3. Torsion Axle:

Torsion axles provide a smoother ride and better suspension than straight or drop axles. They are suitable for heavy-duty applications.

Trailer axles come in different materials, including steel, aluminum, and iron. The choice of material depends on the application and the load capacity required. Steel axles are durable and can handle heavy loads, while aluminum axles are lightweight and suitable for light-duty applications.

Applications of Trailer Axle

Trailer axles are essential components in various fields, including Transportation and Logistics, Agriculture, Construction, Specialty Trailers, and Heavy Equipment Transport. Trailer axles are suitable for these fields due to their load capacity, durability, stability, and safety.

Future Development Trends and Opportunities

The trailer axle market is continually evolving, driven by technological advancements and changing customer needs. The future of trailer axles lies in lightweight and durable materials, improved suspension systems, and environmentally friendly designs.

The rise of e-commerce and home delivery services presents an opportunity for trailer axle manufacturers to develop new products to meet the growing demand for transportation and logistics.

How to Choose a Suitable Trailer Axle

Choosing the right trailer axle is crucial for efficient and safe transportation. Here are some factors to consider when choosing a suitable trailer axle:

1. Determine the Load Capacity:

The load capacity of the trailer axle must match the weight of the trailer and the goods to be transported.

2. Choose the Correct Axle Type:

The type of trailer axle must match the trailer’s size, weight, and the number of axles required.

3. Consider the Axle Length and Width:

The length and width of the trailer axle must match the trailer’s dimensions.

4. Choose the Right Material:

The choice of material depends on the application and the load capacity required.

5. Examine the Suspension System:

The suspension system must provide stability and safety while transporting goods.

6. Match the Axle with the Trailer’s Brake Requirements:

The trailer axle must be compatible with the trailer’s braking system to ensure safe transportation.

Conclusion

Trailer axles are essential components in various fields, enabling efficient and safe transportation of goods. When choosing a trailer axle, it is crucial to consider factors such as load capacity, durability, and compatibility with the trailer’s size and weight. The future of trailer axles lies in technological advancements and environmentally friendly designs.

Author: Dream

All the content of the page is from the Internet, the content is only as a reference for product selection, our products are replacement parts and not original spare parts; we are not the holder of the original trademarks of the content, our products are only suitable for after-sales replacement parts and not original spare parts, our replacement parts can be perfectly adapted to the original spare parts; if you need to buy original spare parts, please contact the original factory to buy. If you want to buy original spare parts, please contact the original supplier for purchase.